Foam

What is foam?

Foam is a product that can be made using many different compounds. Foam generally is producing using a blowing agent. Our foams are stocked anywhere from 3mm to 100mm in thickness, and can be cut and fabricated to suit a wide range of different applications.

What are some foam varieties?

PRP stocks a wide selection of different foams, all which has very unique properties depending on the intended application. All our foams can also come supplied with self-adhesive.

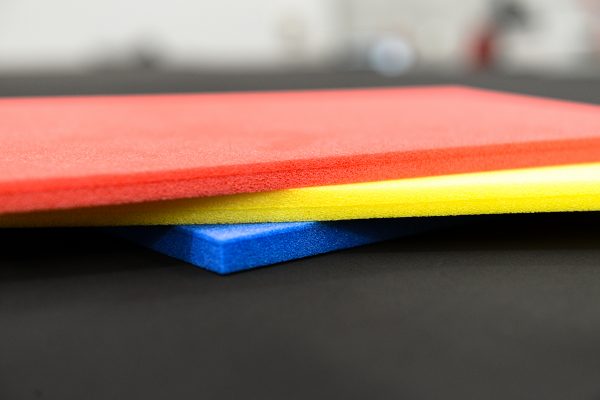

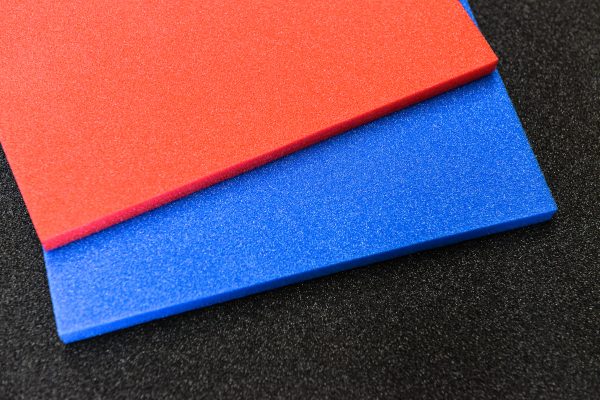

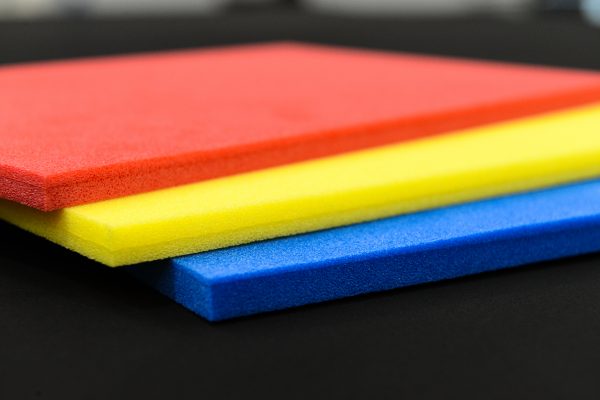

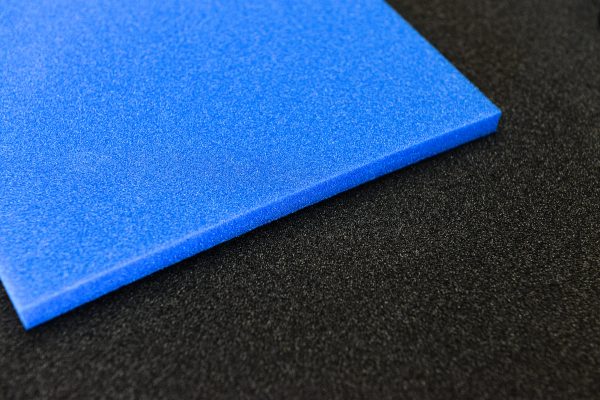

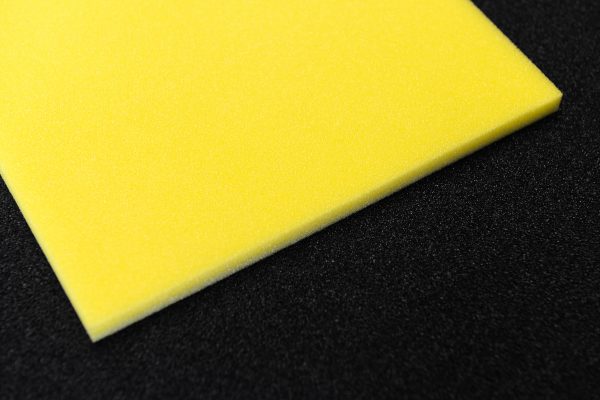

PE and EVA FOAM

Our cross-linked high-quality polyethylene (PE) foam, is available in a wide range of densities and has excellent impact and energy absorption characteristics, making it suitable for many external or internal isolation projects. It is also used extensively within our hard case and custom foam packaging solutions. Similar to PE, our EVA foam is available in similar densities but features greater elongation and compressibility properties than PE. Other similar grades of PE foam can include non-cross linked varieties, specialised PE foams with fire retardant and anti-static properties, and also our Thermoshield range. Thermoshield is a cross-linked PE foam with foil backing. This material, provided in roll forms up to 25mm thick, provides class-leading properties with respect to thermal conductivity and used as an excellent insulating medium.

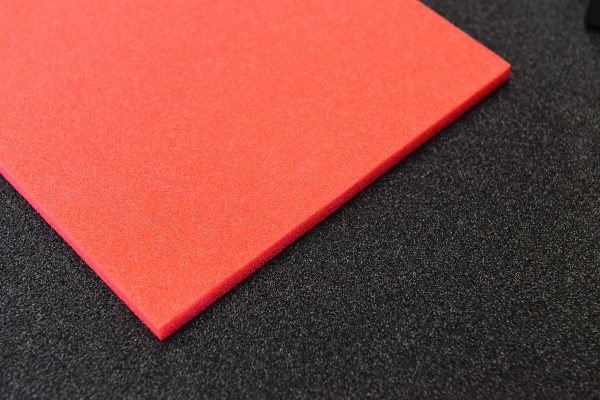

POLYURETHANE FOAM

PRP stocks a range of specialised polyurethane foams. These materials are renowned for having excellent energy absorption characteristics, and have use cases for limiting shock and rebound resistance. They can also support higher temperatures and sometimes preferred to silicone due to their better resistance to abrasion.

SPECIALISED INSULATION FOAM

As part of our specialised insulation foam range, Cello foam is a unique range of products that have class-leading properties in fire retardancy, sound absorption, and thermal properties. The F800 product is polysulfone (PES) in nature, and available in sizes up to 80mm in thickness. The product is soft and pliable, and is able to withstand constant temperatures of up to 150 degrees. The HR290 product has similar performance properties, but instead is produced using a melamine resin. While much more rigid than F800, the product is incredibly light, with a density of just 9.5 kg/m3, and with temperature resistance of up to 180 degrees. These products can be used for a wide variety of wall, flooring, and ceiling applications. Please refer to our datasheets below for more technical information.

OTHER FOAM

In addition to our foam above, PRP also processes types of polyester, polyether and polystyrene varieties. The polyester and polyether’s are much softer in nature and come in a variety of densities. Polystyrene is more rigid and can be used for low-grade packaging requirements.

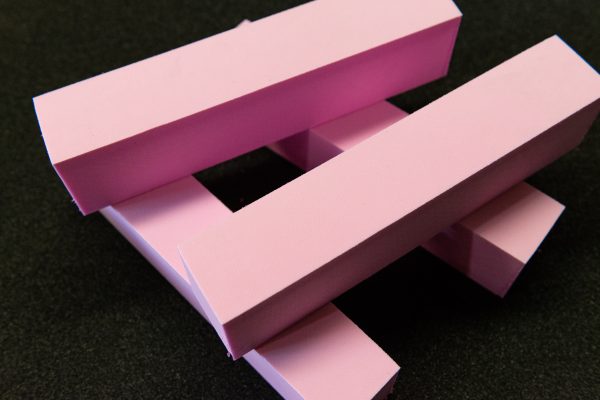

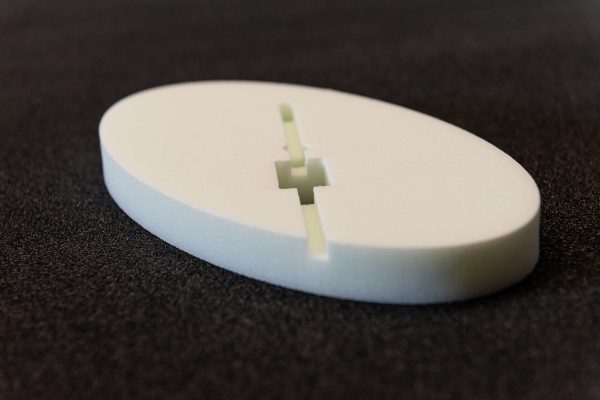

What machinery can foam be cut and fabricated on?

Foam is incredibly versatile and thus can be formed and fabricated on all of our CNC machinery. Our knife cutting technology can generally process almost all foam types. For very high density foams, routering or waterjet technology is often preferred to ensure a nice clean cut and high-quality edge finish. Open cell varieties are avoided on waterjet due to their ability to absorb moisture.

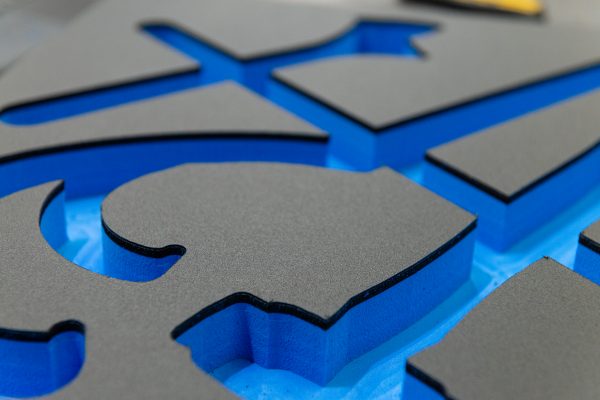

What are some foam applications?

- Packaging foam for custom storage solutions of hard cases.

- Wall, floor or ceiling insulation where reductions in thermal heat transfer or noise are required.

- Blocks and isolators where varying forces and compression are required.