Fiber Sheeting

What is fiber?

Fiber gasket material is made up of non-asbestos fiber mixed with a rubber binder. The product is rolled and vulanised, and is available in many different grades with specific characteristics. Unlike rubber only gasketing materials, fiber sheet has the advantages of being able to cope with higher temperatures, higher pressures, and also tolerate differing chemical requirements.

What are some fiber varieties?

Fiber gasket sheeting comes in a variety of different combinations. Our standard fiber sheet supports temperatures over 200 degrees and pressure upwards of over 50 bar. Other variations can include properties to help with either gas sealability, helping in combat swell caused by oil, or limiting creep in use with oils, fuels and refrigerants. PRP also stocks a specific fiber sheet suitable for resistance against aggressive acids and chemical environments, while out HDS range features high dielectric strength making is an ideal insulating medium. When FDA approved materials our required, our PTFE reinforced fiber sheet satisifies this compliance while offering chemical resistance for a wide variety of different liquids or gases. Finally our graphite and stainless steel impregnated materials offer temperature resistances in excess of 400 degrees, and in some cases pressures withstanding over 150 bar. For more detailed information on our fiber sheeting materials, please feel free to contact us.

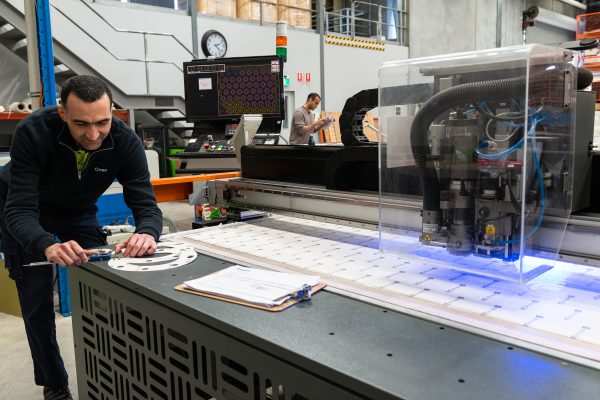

What machinery can fiber be cut and fabricated on?

Fiber sheeting is best cut using either our knife or waterjet cutting technology. Both are capable of cutting the fiber sheeting in all thicknesses, with tight tolerancing and high-quality edge finishes. For some of our graphite variations, knife technology can actually be preferred to reduce the likelihood for fracturing during the initial waterjet pierce stage.

What are some fiber applications?

- Flange gaskets – Ring joint and full face gaskets in compliance to international standards

- Heat exchangers

- Custom tanks and sealing projects with higher temperature, pressure, or chemical requirements