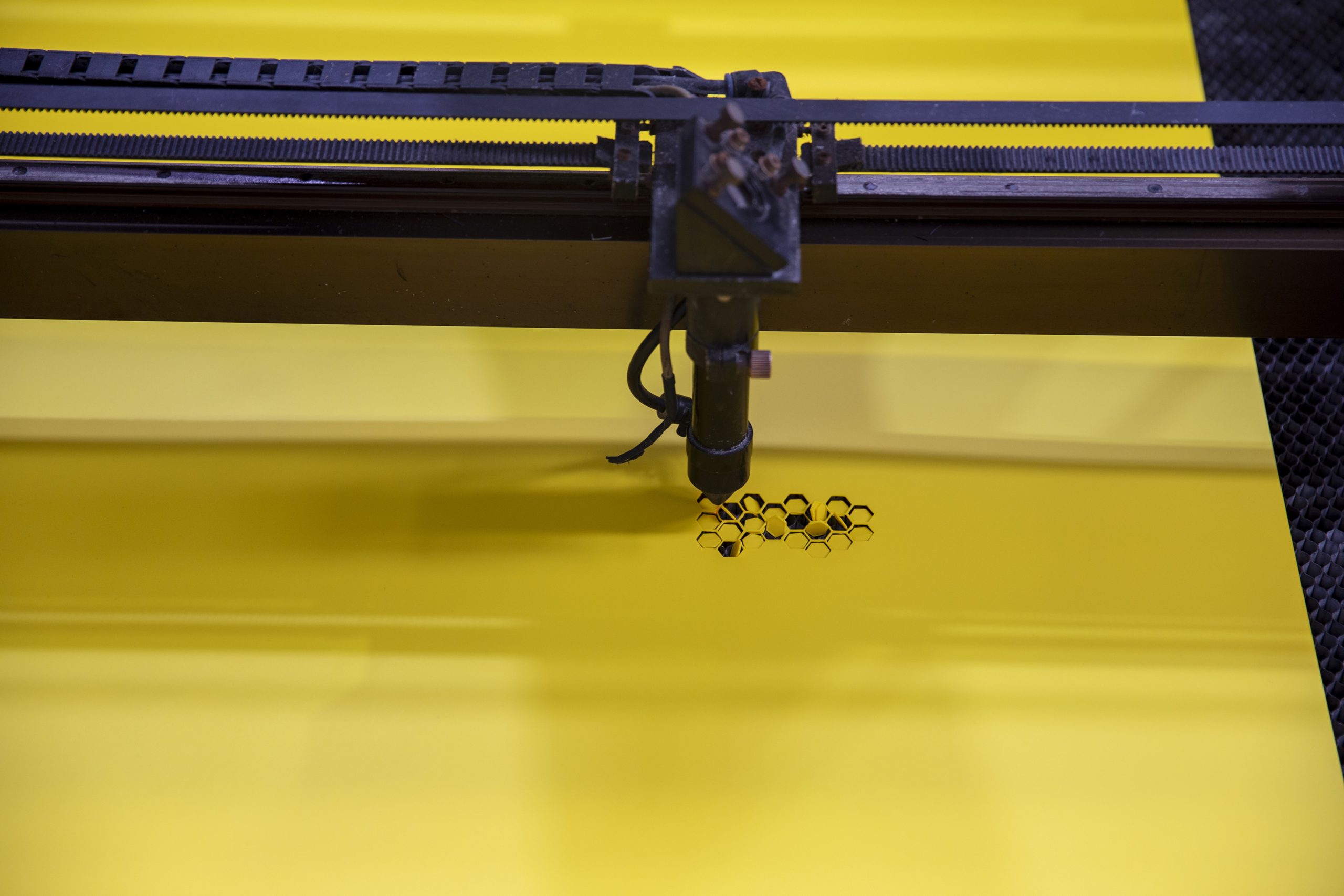

Laser Cutting

What is laser cutting technology?

Laser cutting can use various forms of technology, but the most common are CO2 and Fiber. Low power CO2 lasers are best optimized to cut non-metal materials, such as acrylic, wood, various types of plastic, sponges, and foams. Fiber lasers on the other hand are optimized to cut metals such as mild steel, stainless steel, copper, aluminum and brass.

PRP’s current laser technology uses a CO2 laser to cut a wide range of non-metallic substrates. The machinery has an adjustable bed catering for a range of different thicknesses and profiles. CO2 lasers operate at very low running costs, making them incredibly cost-competitive, even for small batch runs.

What is it’s tolerance?

Positional accuracy can be within +/- 0.05mm, and is an ideal tool where high fidelity or intricacy is required. The laser can be focused to have an incredibly fine cutting profile.

What material does it support?

Our bed size is 1.2m x 1.2m, and height is adjustable to suit different thicknesses or product profiles. CO2 can cut similar materials to that of our knife cutting technology, but because the process uses a beam rather than a physical cutting medium (such as a knife), lasers can produce cleaner cutting lines when it comes to harder plastics such as acrylic. Given lower power CO2 technology is excellent for non-metallic substrates, the following material groups are suitable:

- Thin plastics (such as polypropylene, acrylic, HDPE, polycarbonate, and more*)

- Thin wood and timber

- Leather

- Thin rubbers, sponges, and foams

What are some applications?

- Acrylic cutting with excellent edge finish and fine tolerancing

- Intricate gasket profiles with radius less than 2mm

- Plastic stencils and alphanumeric kits