CNC computer cutting

Waterjet cutting

Waterjet cutting is a technology that uses water at high pressure pumped through a small office to form a jet capable of cutting a vast variety of different substrates.

Waterjet cutting can use water-only for cutting softer materials, while abrasive cutting will allow for the cutting of much harder materials such as steel.

PRP’s waterjet has a 3m long x 1.5m cutting bed, a 305mm high gantry, and is capable of cutting nearly any material bound within the limits of the machine.

This includes rubber, sponge, foam, fiber, plastic, steel, composites, stone, glass and much more!

Knife cutting

Knife cutting technology uses tungsten carbide blades that oscillate at incredibly high speeds.

Our blade technology is available with many different knife profiles, and designed specifically to cut a wide range of soft materials with thicknesses ranging from 0.06mm right up to 100mm thick (all with a single pass).

The blade itself can either be tapered or straight, and the tip of the blade can vary depending on the intricacy of the cut of the finish that is required.

The material is supported on an engineered flatbed, with multiple machines measuring 3m long and 1.5m wide.

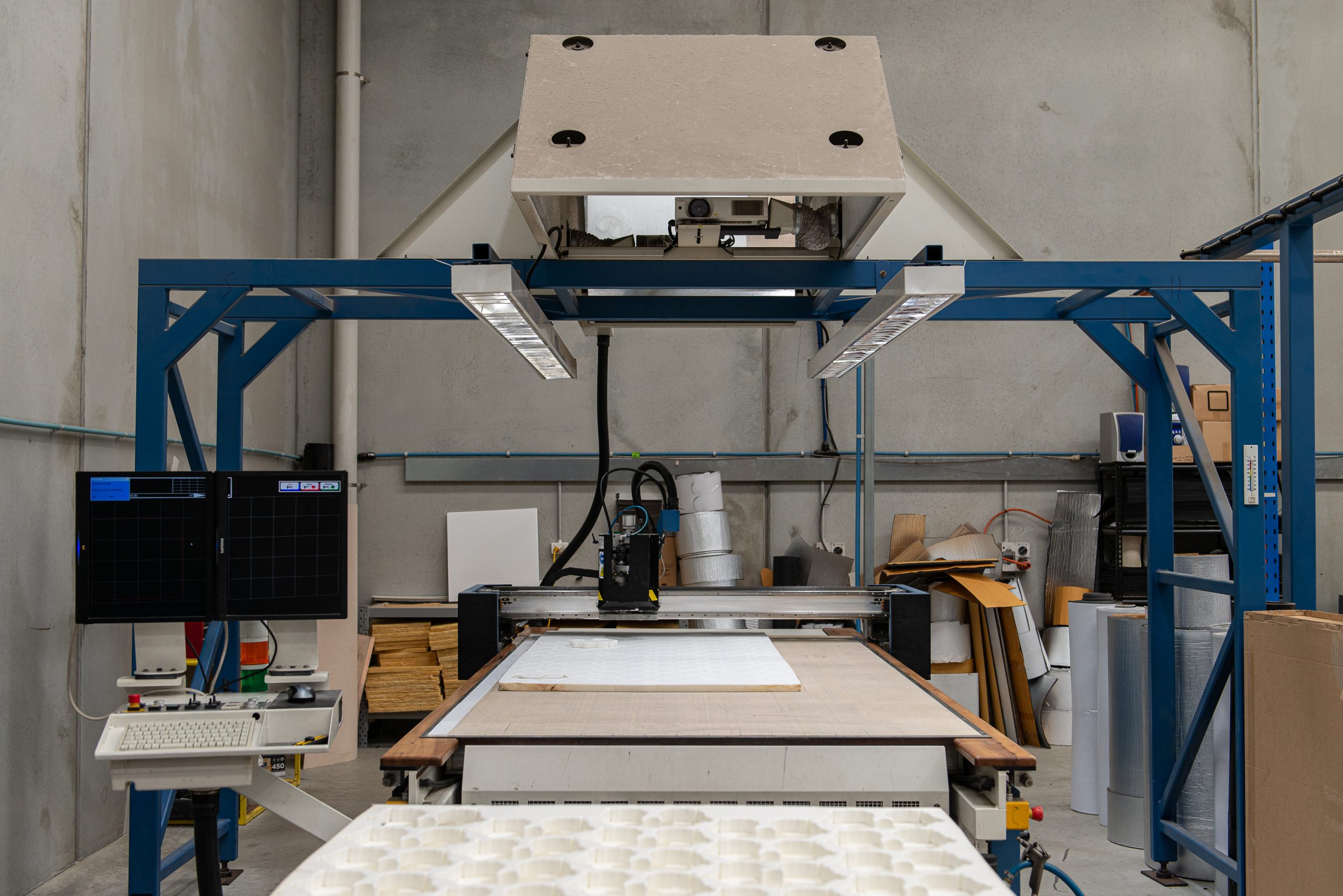

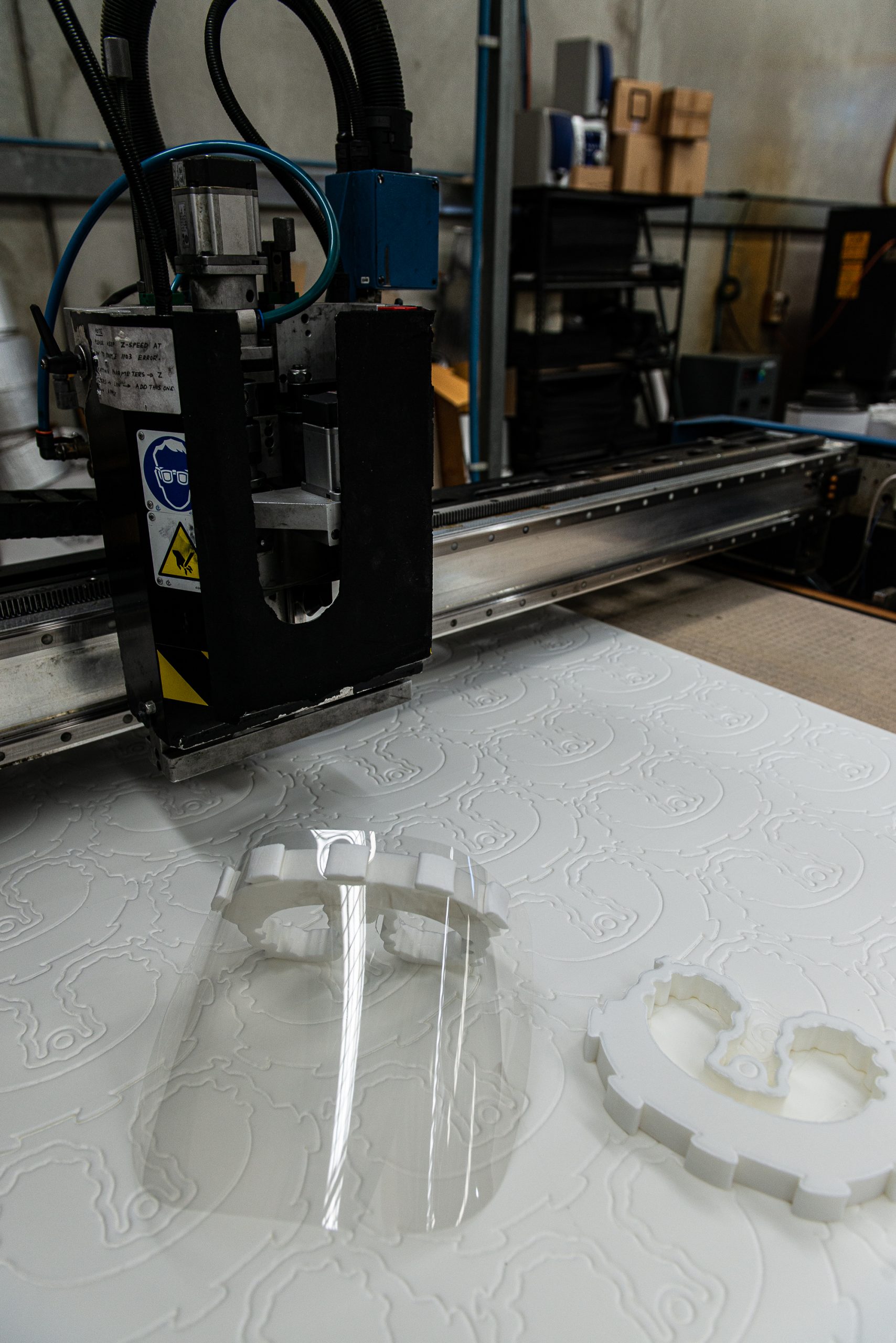

Router cutting

Complimenting knife, water, and laser cutting technology, routering (also can be referred to as milling) can also be used to router our materials.

Unlike cutting technologies, routering uses tool bits that rotate at high RPM to spin and cut away material.

This enables the cutting of harder materials, but also with the added advantage of routering down to a specific depth.

The quality of the finish can be controlled by the rotational speed, the feed rate, and the drill bit itself.

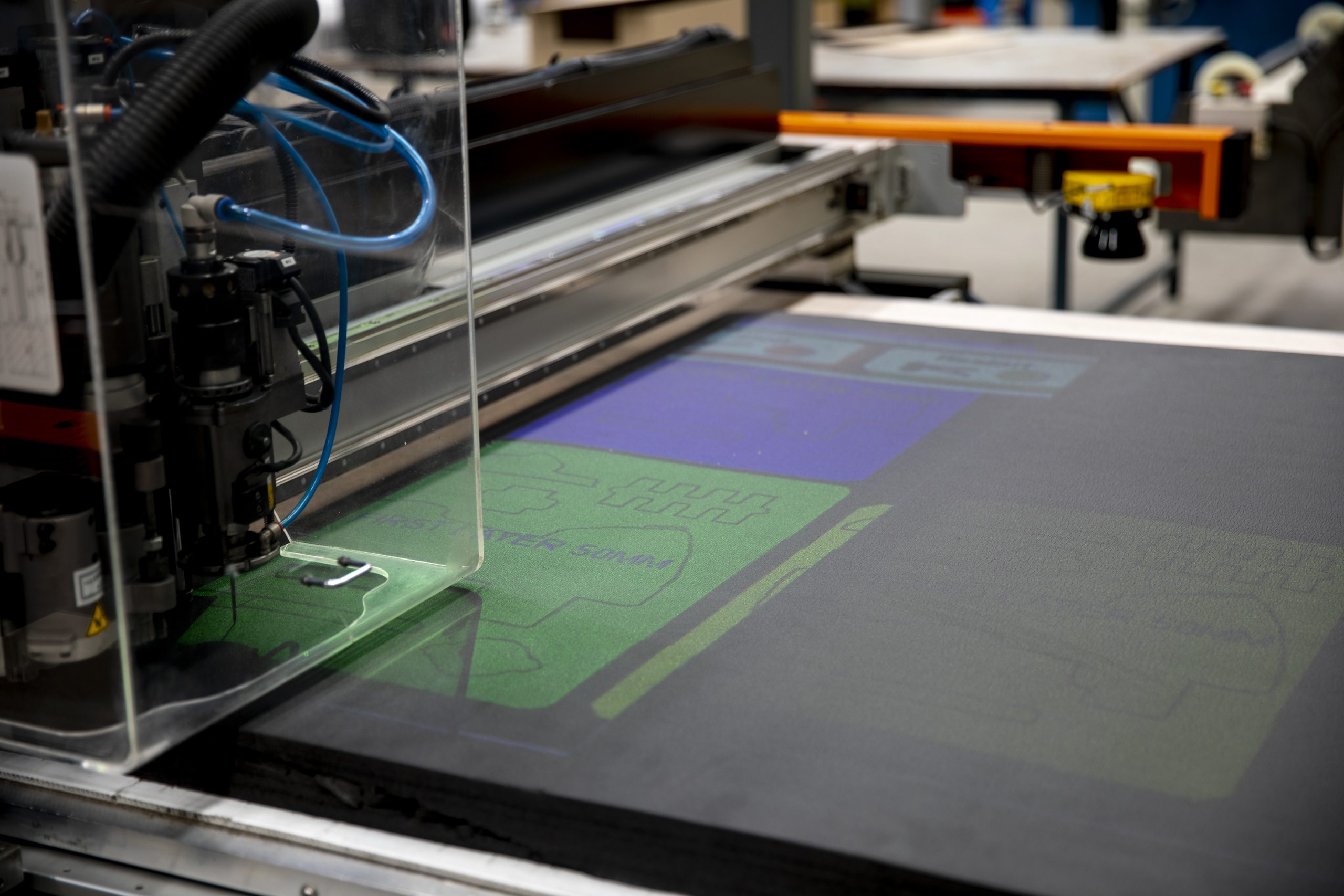

Laser cutting

Laser cutting can use various forms of technology, but the most common types are CO2 and Fiber.

PRP’s current laser technology uses a CO2 laser to cut a wide range of non-metallic substrates such as acrylic, wood, various types of plastic, sponges and foams. Our waterjet technology can be a great substitute for metallic varieties.

The machinery has an adjustable bed catering to a range of different thicknesses and profiles. CO2 lasers operate at very low running costs, making them incredibly cost-competitive even for small batch runs.

Die cutting

PRP features a range of die cutting presses specifically targeting medium to high volume production.

With the ability to fabricate tooling and dies in-house, PRP can produce up to 20,000 units per hour using automated cutting and feeding systems.

While there is an initial cost for tooling, the speed of die cutting means part cost is reduced with NET cost savings over medium to high volume quantities.