Capabilities

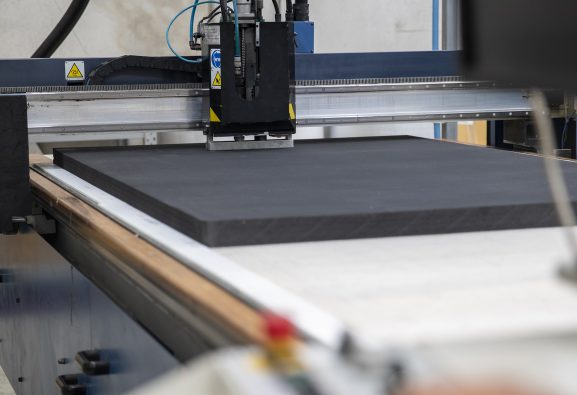

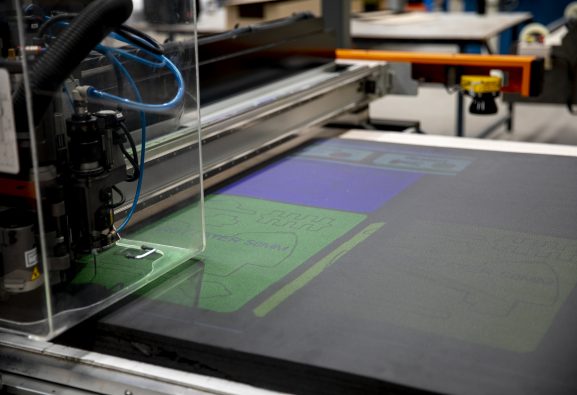

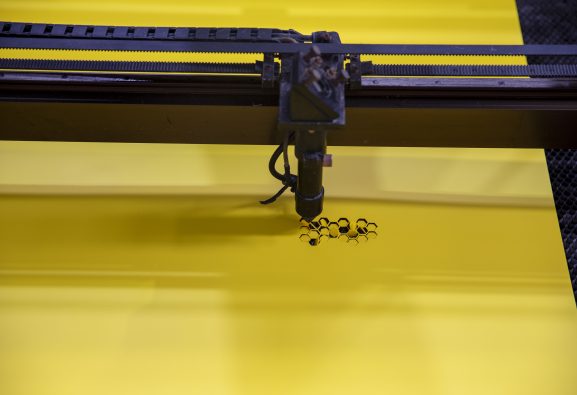

CNC computer cutting

Our bread and butter.

PRP’s CNC machinery consists of numerous flat bed cutting machines, including watejet, knife, routers, lasers and automated high-volume die presses.

Our machinery has the ability to cut a wide range of different materials to tight tolerances and high precision.

PRP has the ability to fabricate prototypes and small batches right through to high volume mass production.

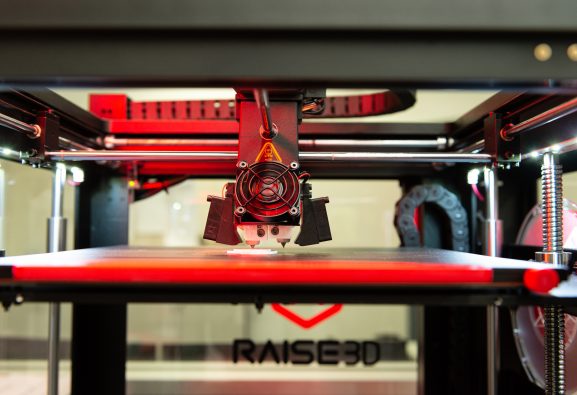

Design and engineering

PRP has an engineering team on site that can assist with any design or technical aspects that could be encountered along the way.

Our team features mechanical engineering experience, specialisation in materials, advanced CAD drafting and industrial design.

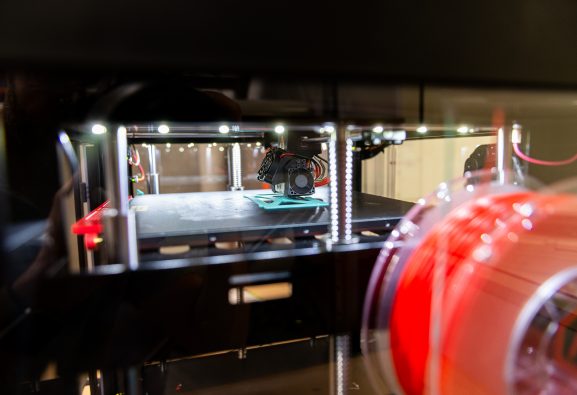

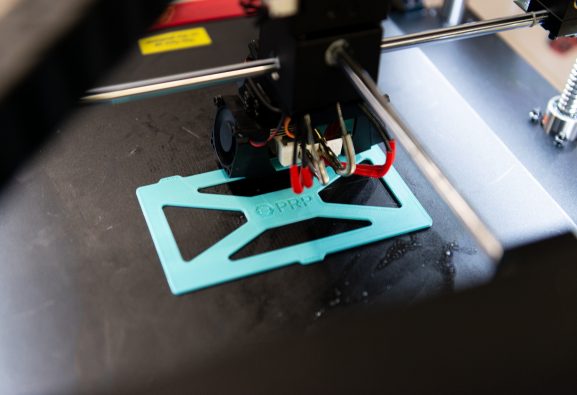

PRP also has on-site a dual head 3d printer capable of prototyping work or even custom made bespoke parts, brackets or fixtures.

Advanced materials

PRP sources a wide range of advanced materials from all over the globe, and continually works with different compounds and substrates with class-leading properties.

PRP stocks many different varieties of rubber, sponge, foam, cork, plastic and fibre, with many of them exhibiting very unique properties with respect to controlling temperature, withstanding heat, very low thermal conductivity, sound dampening, fire retardancy and anti-static.

We work with both in-house materials and also those from our customers and partners.

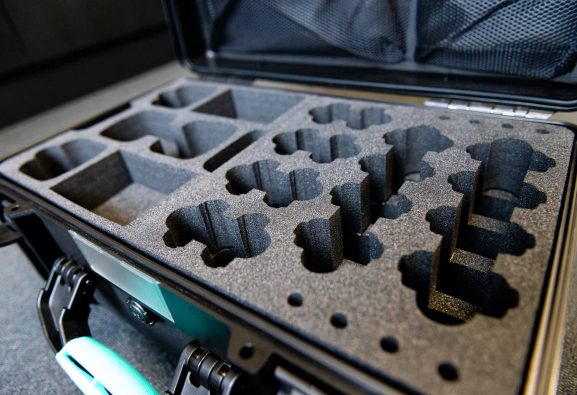

Protective foam and cases

PRP has the ability to produce custom foam inserts for any box, hard case, soft case or enclosure.

Utilising the latest in CNC technology, our inserts can be either cut or milled to produce an accurate and durable insert which profiles the exact contents within the case.

Photography and videography equipment, drones, defence, guns and ammunition, warehouse and logistics, transportation, teaching (education kits utilising VR/AR), tooling, mining equipment, specialty heavy equipment, medical equipment and much much more!

Custom packaging

PRP Manufacturing creates a wide variety of custom packaging solutions, utilising high-quality plastic flute and custom cut foam.

The boxes have excellent structural integrity and are a low-cost alternative for part storage and transfer.

Our boxes are ideal for warehousing, logistics, storage, and streamlining production with smart workflows.

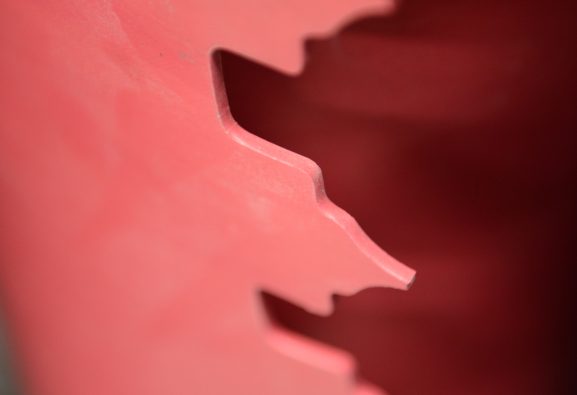

Gaskets, washers & seals

PRP is a leading provider in the manufacturer of industrial gaskets, washers and seals, providing an extensive range of differing solutions to major industries such as defence, mining, energy, agriculture, petrochemical, water and sewage.

PRP has the facilities to CNC machine and die cut a wide variety of rubber, sponge, foam, plastic, fibre and metal impregnated gasket materials, and also provide metallic solutions for a wide range of jointing profiles, including cam profile, spiral wound, corrugated, metal Jacketed and RTJ (ring type joint).

PRP also produces custom sealing solutions for a wide range of applications utilising specialised materials.

Bespoke components

Utilising PRP’s CNC cutting capabilities, and comprehensive fabrication facility, PRP has the capacity for many unique and bespoke requirements.

Extending beyond gaskets, seals and protective packaging, PRP has over the years fabricated custom components over a wide range of different industries.

Examples include custom thermal insulation profiled parts into the HVAC industry, pads, brackets and jigs, high precision milled components to tolerancing down to +/- 0.01mm, to specialised tiny CNC insulating components for use in electronic circuit board assembly.

If you feel our capability could suit our requirements please feel free to contact us!

Quality control

Quality control

PRP is ISO 9001 quality certified, and has an extensive quality management plan to ensure our production processes are efficient, and the products we produce conform to specification.

PRP’s quality objectives are simple.

- Produce products that are free of defects

- Deliver our products in full and on time

- Strive to improve year on year and do what we can to surpass our customers’ expectations

PRP has worked with many prime and tier 1 customers in producing products conforming to ISO 9001:2015 and AS9100 (Aerospace FAI).