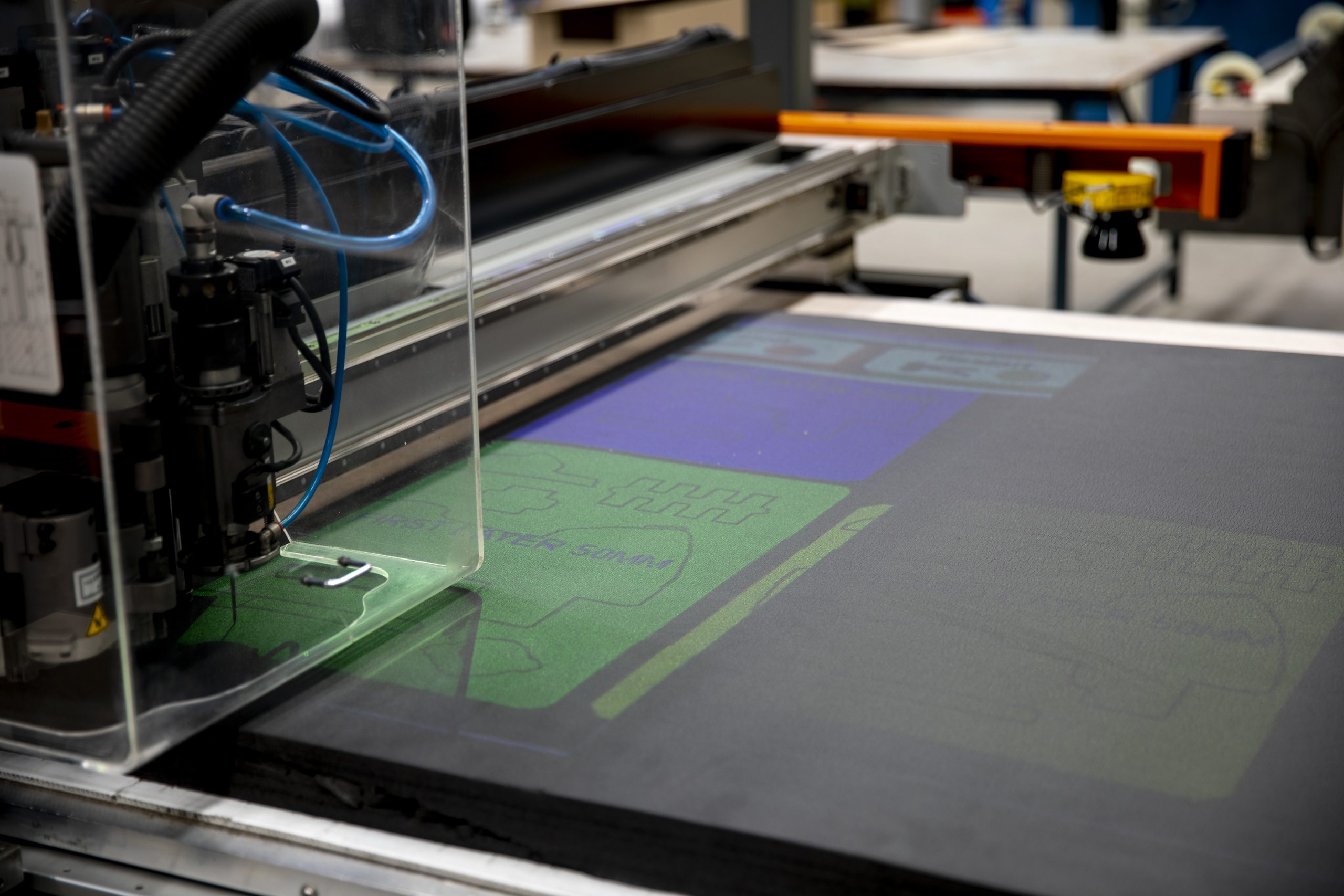

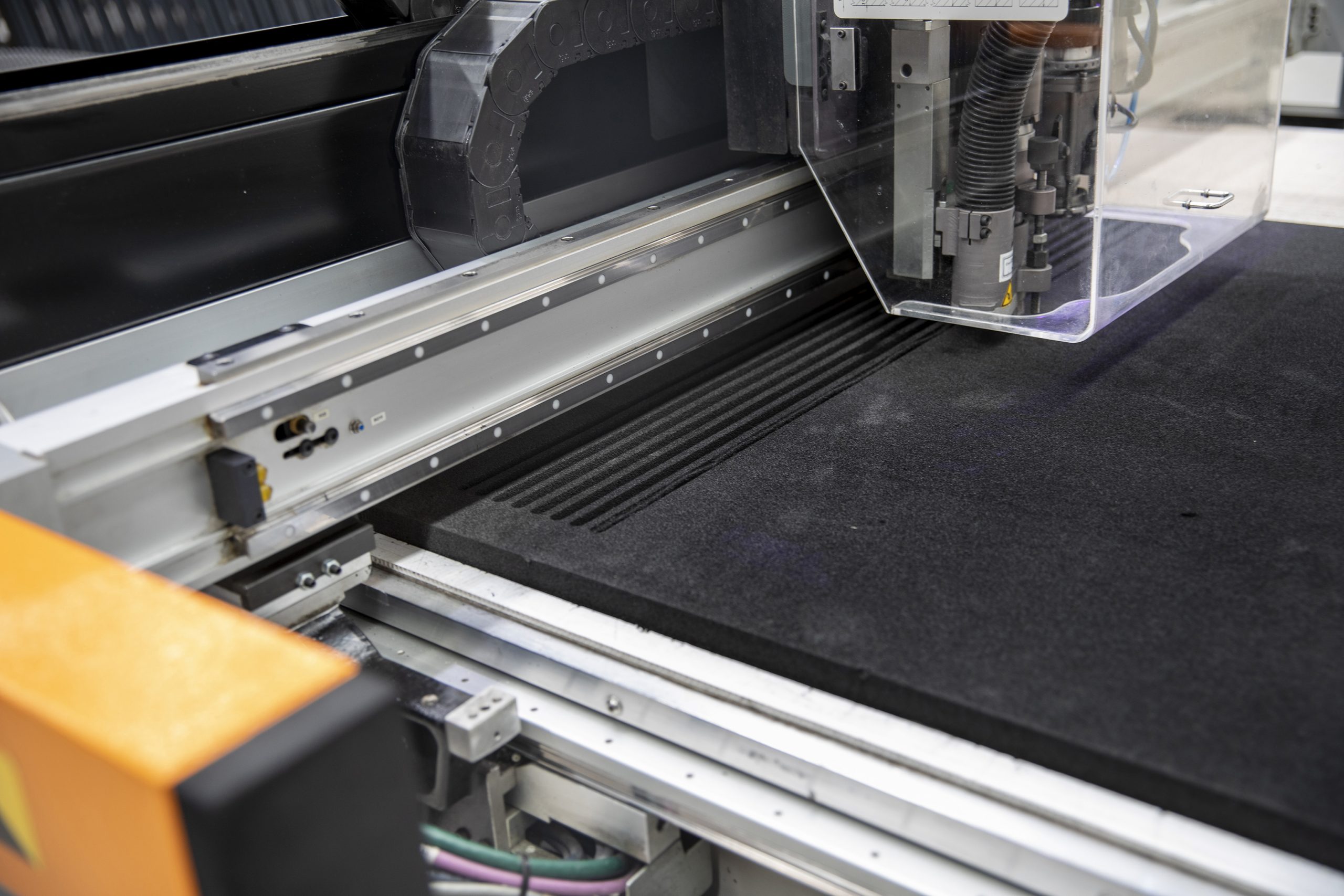

Router Cutting

What is router cutting technology?

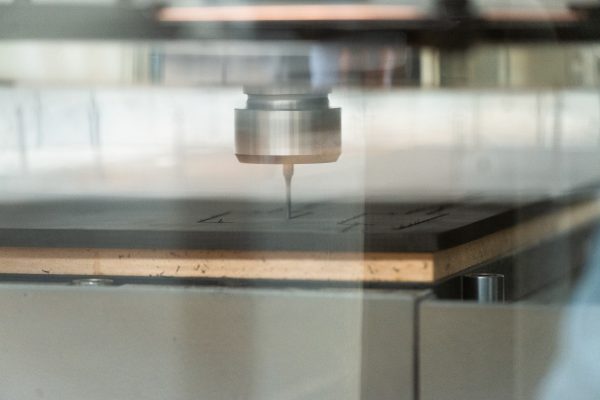

Complimenting knife, water, and laser cutting technology, routering (also can be referred to as milling) can also be used to cut materials. Unlike other cutting technologies, routering uses tool bits that rotate at high RPM to spin and cut material away. This enables the processing of harder materials, but also with the added advantage of routering down to a specific depth, and thus does not need to cut or penetrate through the entire thickness. The quality of the finish can be controlled by the rotational speed, the feed rate, and the drill bit itself.

What is its tolerance?

The machines have similar properties to our flatbed knife machines, featuring a 3.0m x 1.5m bed, vacuum suction assistance, and variable tools and spindles to cut a range of complexities. We can router down to +/- 0.076mm, and our smallest tool bit has a diameter of only 3.2mm, allowing us to perform fine cutting work and tight profiles. A unique advantage of our routing capability is our ability to machine 5-axis products with dedicated tooling and extra high head clearance.

What materials does it support?

Our machinery has been optimized for both soft and medium-density materials. Please refer to the following groups below:

- Sponge and foam

- Plastic (soft and thin)

- Plastic (harder are thick)

- Timber

- Aluminum

What are some applications?

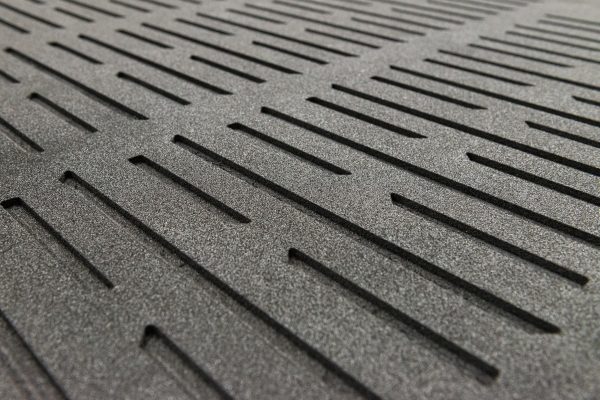

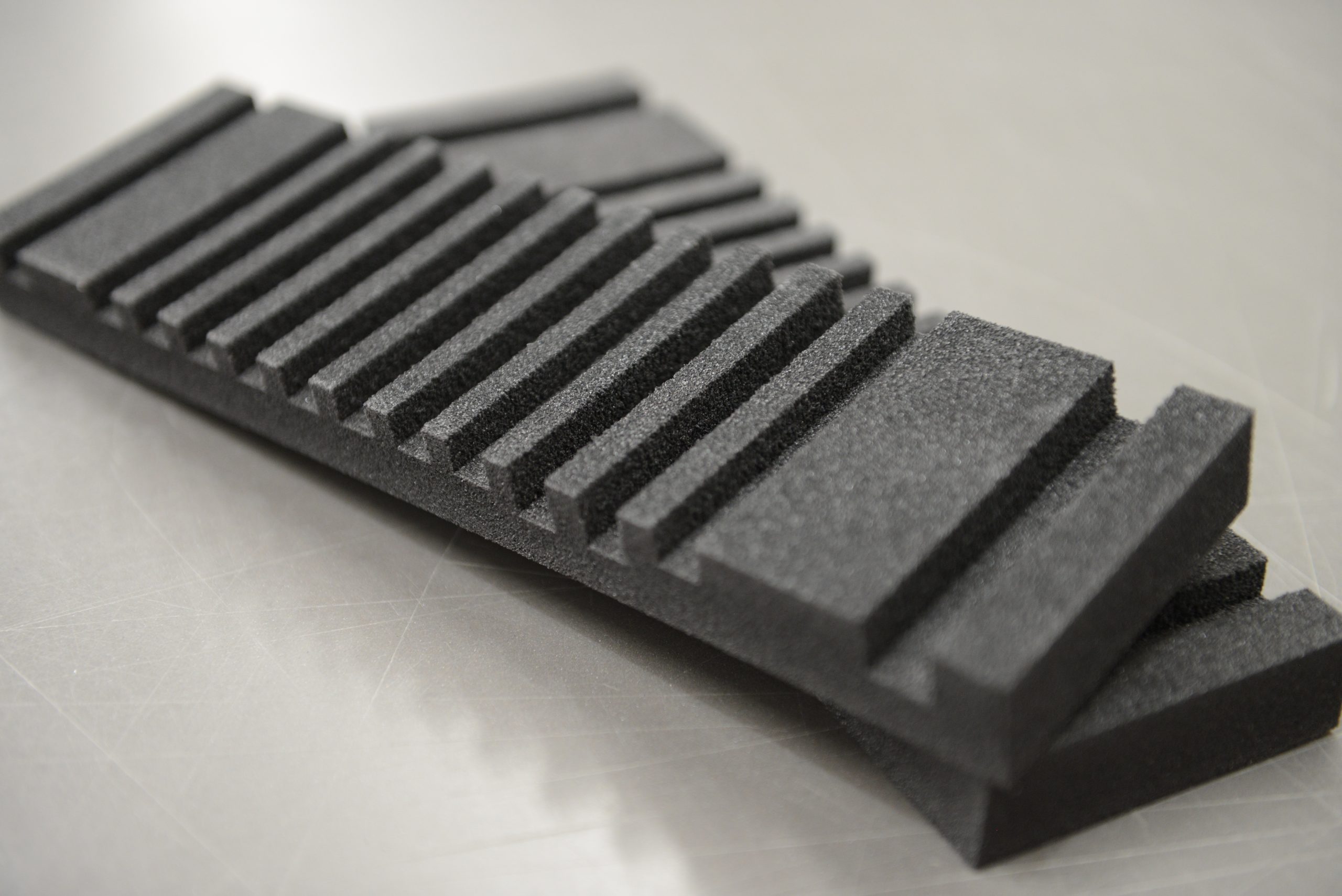

- Protective foam inserts with multiple internal thicknesses or variations

- Box or enclosure routering with internal v-carving to aid folding and bending

- Foam profile with routered grooves for infill and insulation