What we do at PRP

Design & Engineering

2D & 3D ENGINEERING

Our team has mechanical engineering experience, specialisation in materials, advanced CAD drafting, 3D printing and industrial design.

CNC Computer Cutting

WATERJET, LASER, ROUTER, KNIFE, 5-AXIS

PRP’s CNC machinery consists of numerous flat bed cutting machines, including watejet, knife, routers, lasers and automated high-volume die presses.

Advanced Materials

CLASS LEADING PROPERTIES

PRP sources a wide range of advanced materials from all over the globe, and continually works with different compounds and substrates with class-leading properties.

Gaskets & Seals

Ultimate in sealing protection

PRP has the facilities to CNC machine and die cut a wide variety of rubber, sponge, foam, plastic, fibre and metal impregnated gasket materials.

Protective Packaging

HARD CASE AND FOAM INSERTS

PRP provides both hard cases and custom foam insert solutions for a wide range of different applications.

Custom Components

High precision, bespoke solutions

Utilising PRP’s CNC cutting capabilities, and comprehensive fabrication facility, PRP has the capacity for many unique and bespoke requirements.

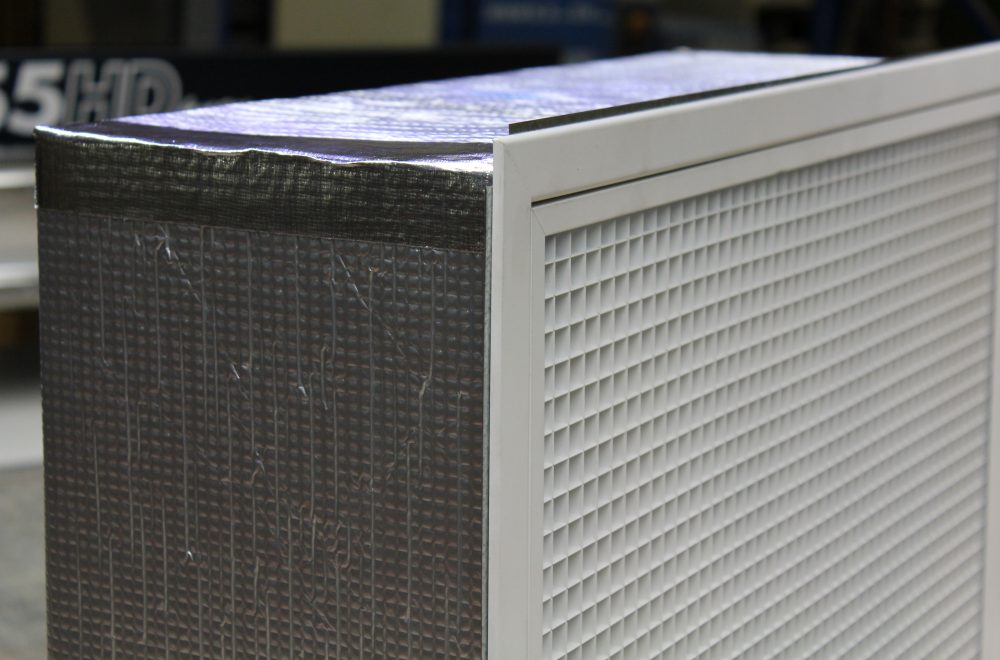

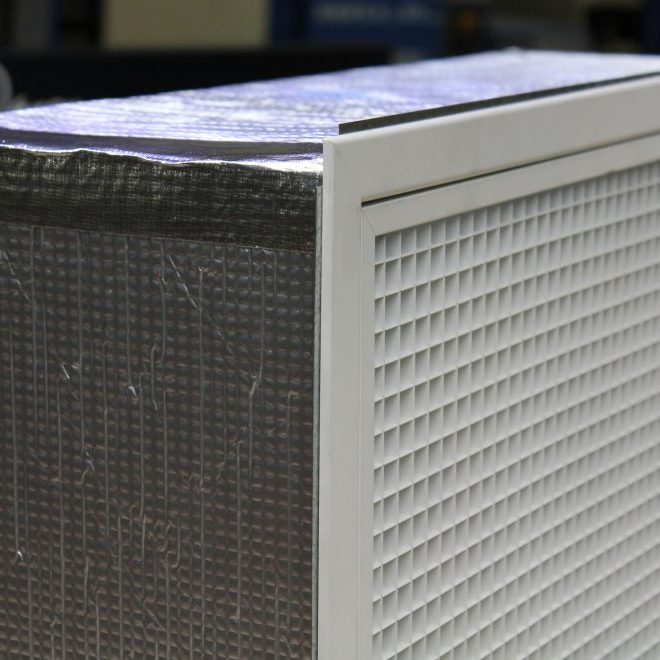

Foam insulation

Sound and thermal

PRP stocks a range of specialised sponges and foam with class leading thermal, sound and fire-resistant properties.

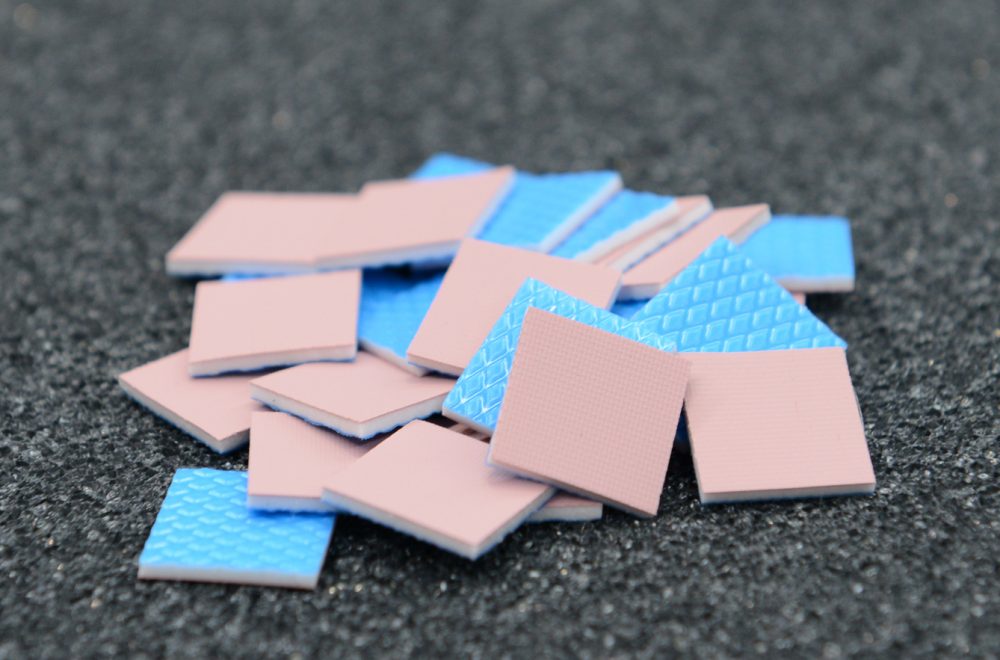

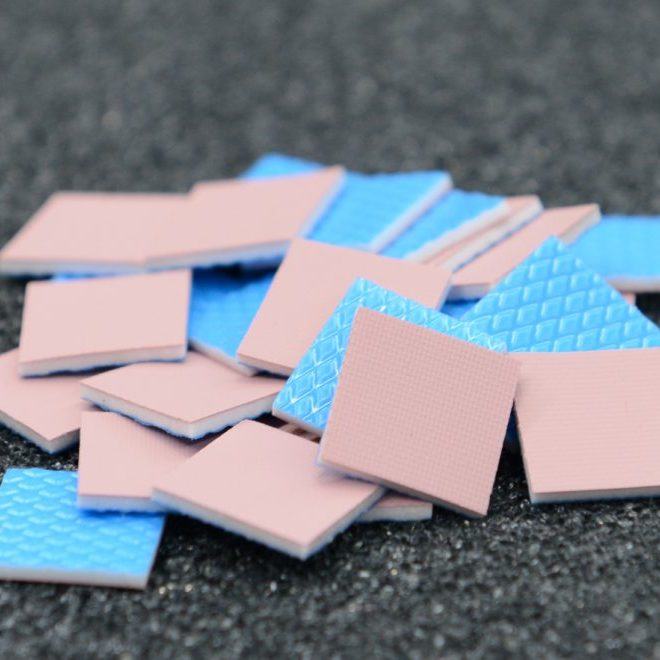

Electronics management

Thermal, EMI, RCS reduction

Thermal gap pads, EMI shielding materials, and microwave-absorbing materials are essential in managing the thermal and electromagnetic environments of advanced electronic systems.

Who we are

Founded in 1991, PRP uses advanced CNC cutting technology and in-house engineering to custom manufacturer a wide range of products out of very advanced materials.

PRP Manufacturing is committed to solving our customer’s problems, by inspiring excellence through creative innovation and continuous improvement.